Application of Off Grid Inverters on Remote Farms

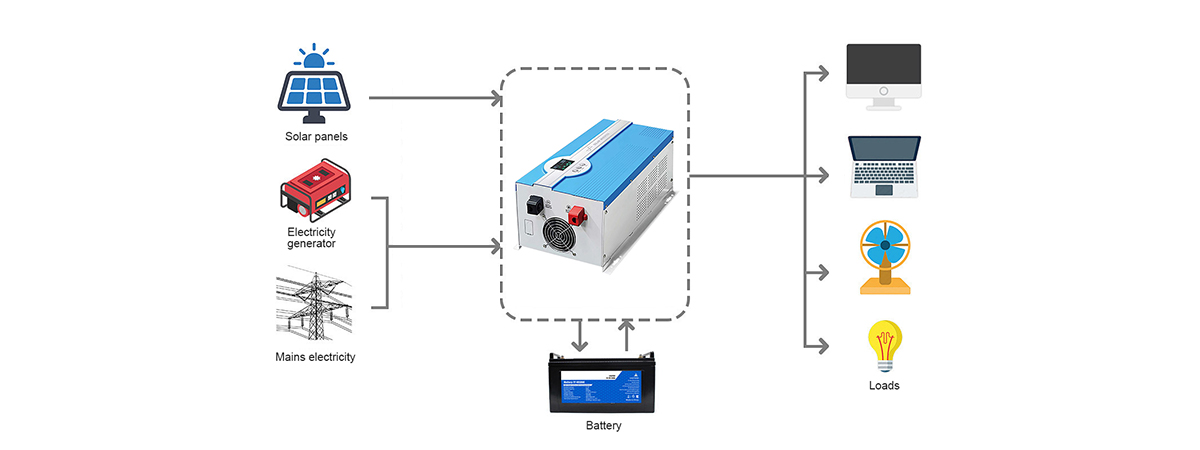

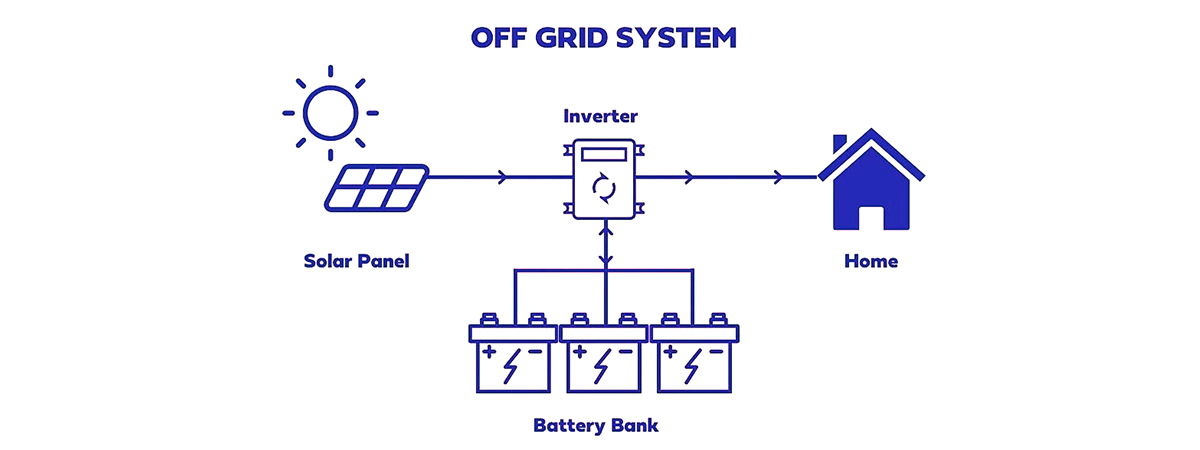

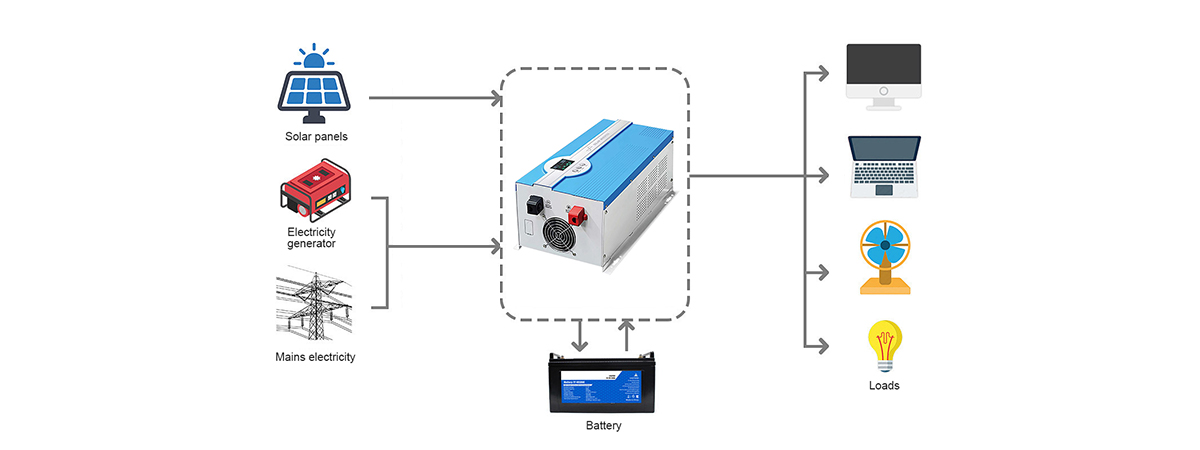

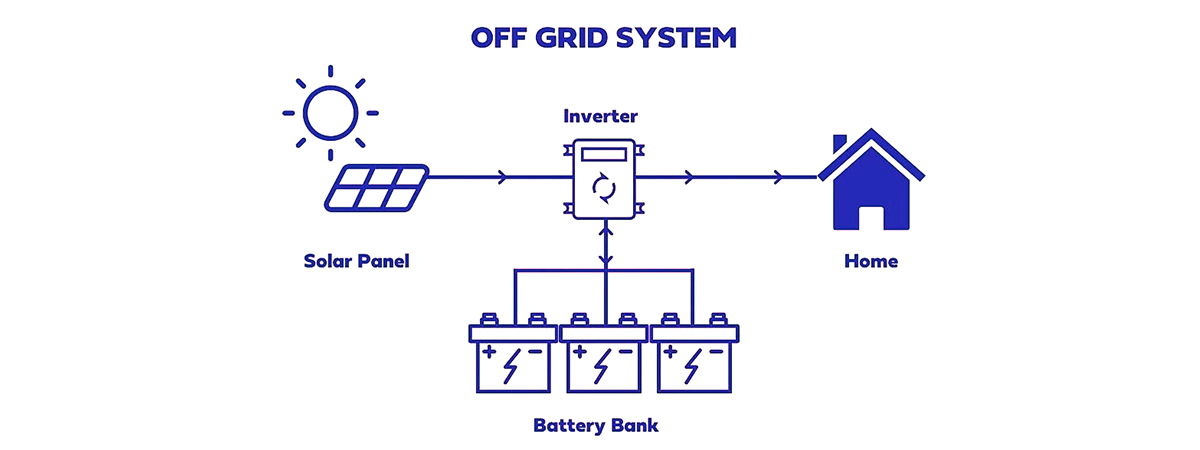

An off-grid inverter is a device that converts direct current (DC) generated by solar panels into alternating current (AC) and stores it in batteries, making it suitable for remote areas without grid access. With advancements in renewable energy technology, off-grid inverter systems from various manufacturers are increasingly being applied in remote areas. This case study aims to explore the application of off-grid inverters on a remote farm, evaluating their economic and environmental benefits, and sharing users' real experiences.

2. Inverter Selection: An 8 kW off-grid inverter was chosen, paired with 40 polycrystalline solar panels, each with a capacity of 250 watts, totaling 10 kW, along with a 48-volt lithium battery pack with a total storage capacity of 40 kWh. Polycrystalline solar panels were selected for their cost-effectiveness and suitability for large-scale use.

3. System Configuration and Layout: The solar cell panels were installed in various areas of the farm to maximize sunlight absorption. The inverter and battery pack were installed in the farm's warehouse for easy maintenance and management.

2. Operating and Maintenance Costs: The system's maintenance costs are low, mainly involving periodic inspections and battery replacement, with an annual maintenance cost of about $400.

3. Diesel Cost Savings and Payback Period: After installation, the diesel generator was no longer used, saving about $800 per month in diesel costs, or approximately $9,600 annually. The estimated payback period is 5.2 years, after which the farm can enjoy at least 15 years of low-cost power.

2. Positive Environmental Impact: By reducing reliance on diesel, the system helps alleviate environmental pollution, improving local air quality and the ecological environment.

2. Challenges and Solutions: The main challenge was the high initial investment cost, which was addressed through agricultural loans and government subsidies. During installation, the complex terrain of the farmland posed difficulties, which were resolved through optimized system layout planning and designing.

Case Background

This case study focuses on a farm located in a remote mountainous area of Montana, covering approximately 100 hectares. The farm primarily engages in livestock breeding and crop cultivation. Due to its remote location, the farm cannot access the grid and relies mainly on diesel generators for power, which are costly and highly polluting. To address the power issue, the farm decided to install an off-grid inverter system.

Off-Grid Inverter Installation and Configuration

1. Installation Process: The installation process included assessing power needs, system design, equipment procurement, installation of solar panels, grid off inverter, and battery pack, system commissioning, and training. The entire installation took about a month and was completed jointly by a professional company and farm personnel.2. Inverter Selection: An 8 kW off-grid inverter was chosen, paired with 40 polycrystalline solar panels, each with a capacity of 250 watts, totaling 10 kW, along with a 48-volt lithium battery pack with a total storage capacity of 40 kWh. Polycrystalline solar panels were selected for their cost-effectiveness and suitability for large-scale use.

3. System Configuration and Layout: The solar cell panels were installed in various areas of the farm to maximize sunlight absorption. The inverter and battery pack were installed in the farm's warehouse for easy maintenance and management.

Economic Benefit Analysis

1. Initial Investment Cost: The total investment cost was approximately $50,000, including equipment procurement, installation fees, and the net cost after tax incentives.2. Operating and Maintenance Costs: The system's maintenance costs are low, mainly involving periodic inspections and battery replacement, with an annual maintenance cost of about $400.

3. Diesel Cost Savings and Payback Period: After installation, the diesel generator was no longer used, saving about $800 per month in diesel costs, or approximately $9,600 annually. The estimated payback period is 5.2 years, after which the farm can enjoy at least 15 years of low-cost power.

Environmental Benefit Analysis

1. Carbon Emission Reduction: The system can reduce carbon dioxide emissions by approximately 25 tons annually, equivalent to planting 750 trees. The aim of reducing carbon emissions is in line with EnterSolar philosophy.2. Positive Environmental Impact: By reducing reliance on diesel, the system helps alleviate environmental pollution, improving local air quality and the ecological environment.

User Feedback and Experience

1. Usage Experience: The farm owner is very satisfied with the performance of the off-grid inverter system, particularly its ability to provide stable power during peak usage and at night. The system operates stably, and its intelligent management features have improved energy efficiency.2. Challenges and Solutions: The main challenge was the high initial investment cost, which was addressed through agricultural loans and government subsidies. During installation, the complex terrain of the farmland posed difficulties, which were resolved through optimized system layout planning and designing.