Application of Micro Inverters in Agriculture

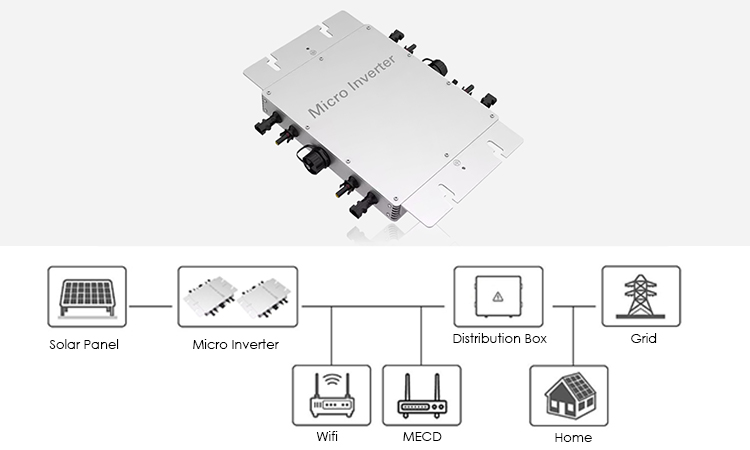

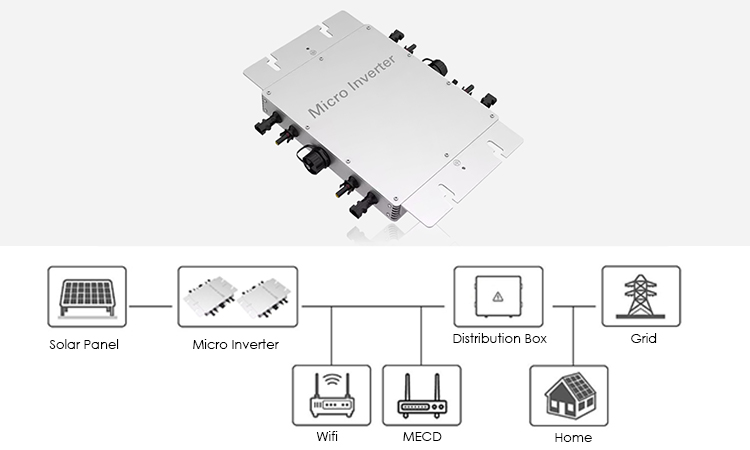

Solar micro inverters can convert the direct current (DC) generated by each solar panel into alternating current (AC) individually, offering high efficiency and modular advantages. This case study aims to explore the application of micro-inverters in an agricultural farm, evaluate its economic and environmental benefits, and share user experiences.

2. Micro-Inverter Selection: The system included 60 monocrystalline silicon solar panels, each with a power output of 320 watts, totaling an installed capacity of 19.2 kilowatts. Each solar panel was equipped with a solar power micro inverter to ensure efficient system operation.

Case Background

The farm in this case study is located in the suburbs of Lincoln, Nebraska, primarily cultivating corn and wheat. The farm covers an area of approximately 200 hectares. Electricity on the farm is mainly used for irrigation and farm machinery, with a monthly average consumption of about 6,000 kilowatt-hours. To reduce electricity costs and improve energy efficiency, the farm decided to install a micro nverter system. Advanced solar inverters also enhance monitoring and system efficiency.

Microinverter Installation and Configuration

1. Installation Process: The installation process included assessing electricity needs, designing the system layout, procuring equipment, installing the micro inverters, connecting to the grid, and commissioning. The process took about a month and was completed by a professional company to design and custom.2. Micro-Inverter Selection: The system included 60 monocrystalline silicon solar panels, each with a power output of 320 watts, totaling an installed capacity of 19.2 kilowatts. Each solar panel was equipped with a solar power micro inverter to ensure efficient system operation.

3. System Configuration and Layout: Solar pv panels were distributed across different locations on the farm to maximize sunlight absorption. Micro-inverters were installed directly behind each solar panel, simplifying system wiring and management.

2. Operation and Maintenance Costs: The maintenance cost of the photovoltaic micro inverter system is relatively low, mainly involving periodic inspections and occasional inverter replacements, with an annual maintenance cost of about $300.

3. Savings on Electricity Bills and Payback Period: After installation, the monthly electricity bill was reduced from $1,200 to $400, resulting in annual savings of about $9,600. The projected payback period is around four years, followed by at least 15 years of low-cost electricity use.

2. Positive Environmental Impact: By reducing reliance on traditional fossil fuels, the system helps mitigate environmental pollution and contributes to improving local air quality. Because EnterSolar is a supplier which committed to providing clean energy.

2. Challenges and Solutions: The main challenge was the high initial investment cost, which was addressed through agricultural loans and government subsidies. During installation, complex terrain on the farm was encountered and resolved by optimizing the system layout.

Economic Benefit Analysis

1. Initial Investment Cost: The total investment cost was approximately $35,000, including equipment procurement, installation fees, and the net cost after tax incentives.2. Operation and Maintenance Costs: The maintenance cost of the photovoltaic micro inverter system is relatively low, mainly involving periodic inspections and occasional inverter replacements, with an annual maintenance cost of about $300.

3. Savings on Electricity Bills and Payback Period: After installation, the monthly electricity bill was reduced from $1,200 to $400, resulting in annual savings of about $9,600. The projected payback period is around four years, followed by at least 15 years of low-cost electricity use.

Environmental Benefit Analysis

1. Reduction in Carbon Emissions: The system reduces approximately 30 tons of carbon dioxide emissions annually, equivalent to planting 900 trees.2. Positive Environmental Impact: By reducing reliance on traditional fossil fuels, the system helps mitigate environmental pollution and contributes to improving local air quality. Because EnterSolar is a supplier which committed to providing clean energy.

User Feedback and Experience

1. User Experience: The farm owner is very satisfied with the performance of the micro-inverter system, particularly its ability to provide stable power during peak irrigation periods. The system operates stably, and its modular design facilitates maintenance and management.2. Challenges and Solutions: The main challenge was the high initial investment cost, which was addressed through agricultural loans and government subsidies. During installation, complex terrain on the farm was encountered and resolved by optimizing the system layout.